Throat, 3D Printer Extruder, All Products

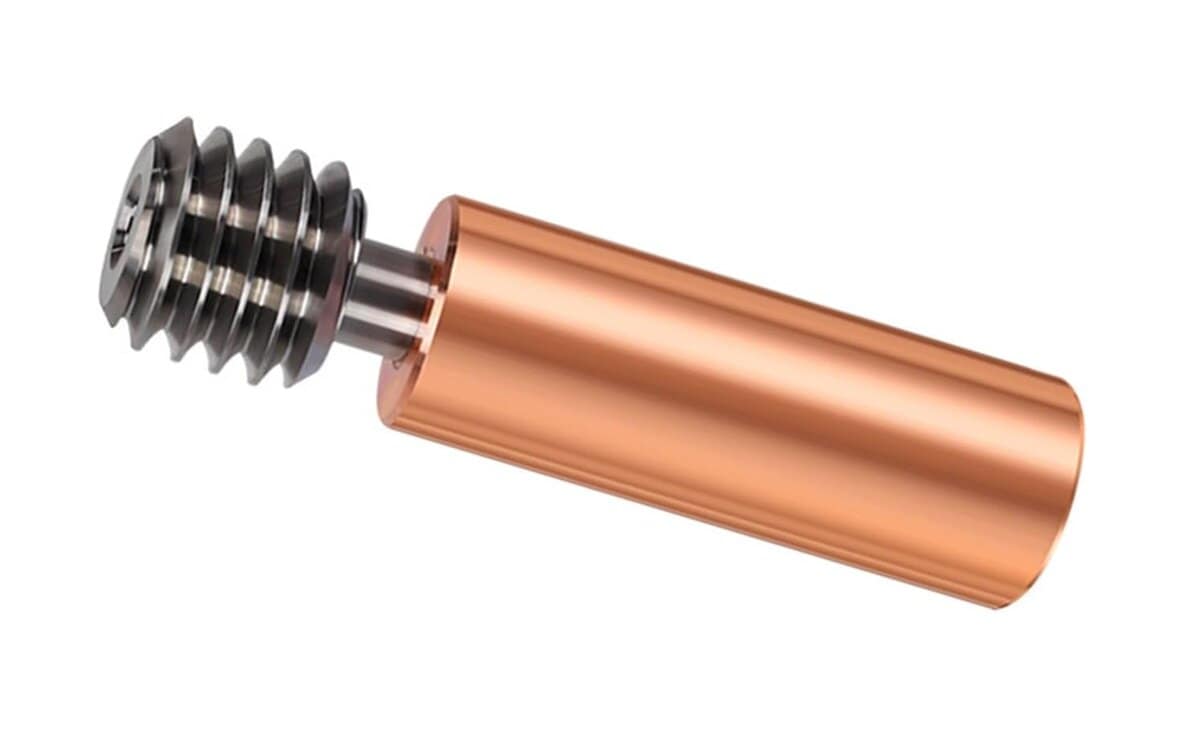

Bimetal Heatbreak for Neptune 4 Hotend 1.75mm Throat Alloy Copper Plate Tube for Neptune 4 3D Printer

Availability:

In stock

₹165.00

Discount per Quantity

| Quantity | 5 - 10 | 11 - 20 | 20 + |

|---|---|---|---|

| Discount | 2% | 4% | 6% |

| Price | ₹161.70 | ₹158.40 | ₹155.10 |

In stock

Tell us what you need and we’ll help you source it.

Bimetal Heatbreak for Neptune 4 Hotend 1.75mm Throat Alloy Copper Plate Tube for Neptune 4 3D Printer

The bimetal heatbreak for the Neptune 4 hotend is an advanced component designed to enhance the efficiency and performance of your 3D printer extruder.

- This particular bimetal heatbreak features a 1.75mm throat alloy copper plate tube, making it a specialized part for the Neptune 4 3D printer.

Specifications of the Bimetal

- The bimetal heatbreak is composed of two distinct metals, typically copper and stainless steel.

- The copper alloy ensures excellent thermal conductivity, which helps in maintaining a stable temperature during the printing process.

- The stainless steel component provides structural durability, ensuring a long-lasting performance even under high-temperature conditions.

- The 1.75mm throat diameter is optimized for precision filament guidance, reducing the likelihood of clogs and ensuring smooth extrusion.

Applications of the Bimetal Heatbreak

- This is specifically designed for usage in the Neptune 4 hotend.

- Its application spans various 3D printing tasks, from prototyping to producing end-use parts.

- By incorporating this heatbreak, users can achieve higher print quality and more accurate temperature control, which is crucial for printing with both standard and specialty filaments.

Advantages and Usages

- The primary advantage of the bimetal heatbreak lies in its ability to efficiently manage heat transfer.

- The copper section rapidly conducts heat, while the stainless steel part acts as a thermal barrier, preventing heat from creeping up to the cold end.

- This balance ensures that the filament remains at an optimal temperature, reducing the risk of heat-related issues such as jamming or filament degradation.

- Furthermore, the bimetal heatbreak is easy to install and compatible with the Neptune 4 hotend, making it a valuable upgrade for enhancing the performance of your 3D printer.

- Its robust construction ensures consistent results, whether you are working on high-detail models or large-scale prints.

- In summary, the bimetal heatbreak for the Neptune 4 hotend with a 1.75mm throat alloy copper plate tube is a critical component that can significantly improve your 3D printing experience.

- Its superior thermal management and durability make it an excellent choice for anyone looking to optimize their Neptune 4 3D printer.

- Investing in this high-quality heatbreak ensures better print quality, reduced maintenance, and overall enhanced performance.

Package Include

- 1 piece of Neptune 4 throat.

| Weight | 5 g |

|---|---|

| Thread | M6 |

| HSN code | 8477 |

| Height | 2.75cm |

| Width | 0.7cm |

| Temperature | 450 – 500 deg Celsius |

Add a review

You must be logged in to post a review

Log In

Q & A

Ask a question

Does this fit to Neptune 4 Pro?

No it won't

(0)

(0)

Add an answer

What is the inner diameter of the throat PTFE area?

1.75mm

(0)

(0)

Add an answer

2 reviews for Bimetal Heatbreak for Neptune 4 Hotend 1.75mm Throat Alloy Copper Plate Tube for Neptune 4 3D Printer