CR10 Heatsink Hotend Extruder Kit Heat Sink for CR10 CR10S 3D printer

In stock

₹129.00

In stock

Tell us what you need and we’ll help you source it.

CR10 Heatsink Hotend Extruder Kit Heat Sink for CR10 CR10S 3D printer:

The CR10 Heatsink Hotend Extruder Kit Heat Sink is a high-quality aluminum block designed specifically for 3D printers in the CR-10 series, including CR-10, CR-10mini, CR-10S, CR-10S4, and CR-10S5.

- Aluminum heat sink heat sink radiator is a must-have component for maintaining optimal temperature control during printing.

Enhanced Cooling Efficiency

The CR10 Heatsink is engineered with precision to provide enhanced cooling efficiency for your 3D printer. Its innovative design allows for better heat dissipation, keeping the temperature of your printer’s hotend at an optimal level. This ensures consistent and high-quality prints, reducing the risk of filament jams and other printing issues.

Durable and Reliable

Constructed from high-quality materials, the CR10 Heat sink is built to last. Its sturdy construction ensures durability, even under high-temperature conditions. You can rely on this heatsink to provide long-lasting cooling performance, allowing you to focus on your printing projects without worrying about overheating.

Easy Installation

The CR10 Heatsink is designed for easy installation. With its user-friendly design, you can quickly and effortlessly attach it to your CR10 series 3D printer. No complex tools or technical expertise required. Simply follow the provided instructions, and you’ll have your heatsink installed in no time.

Features:

- Compatibility: This heat sink radiator is compatible with 3D printers in the CR-10 series and Ender-3.

- Durable Material: Made from solid aluminum alloy, the Heatsink ensures long-lasting performance.

- Lightweight and Efficient: With its lightweight design, the heat sink offers excellent heat dissipation performance.

- Easy to Install: The side lock screw hole and small size make it easy for DIY enthusiasts to install on their 3D printers.

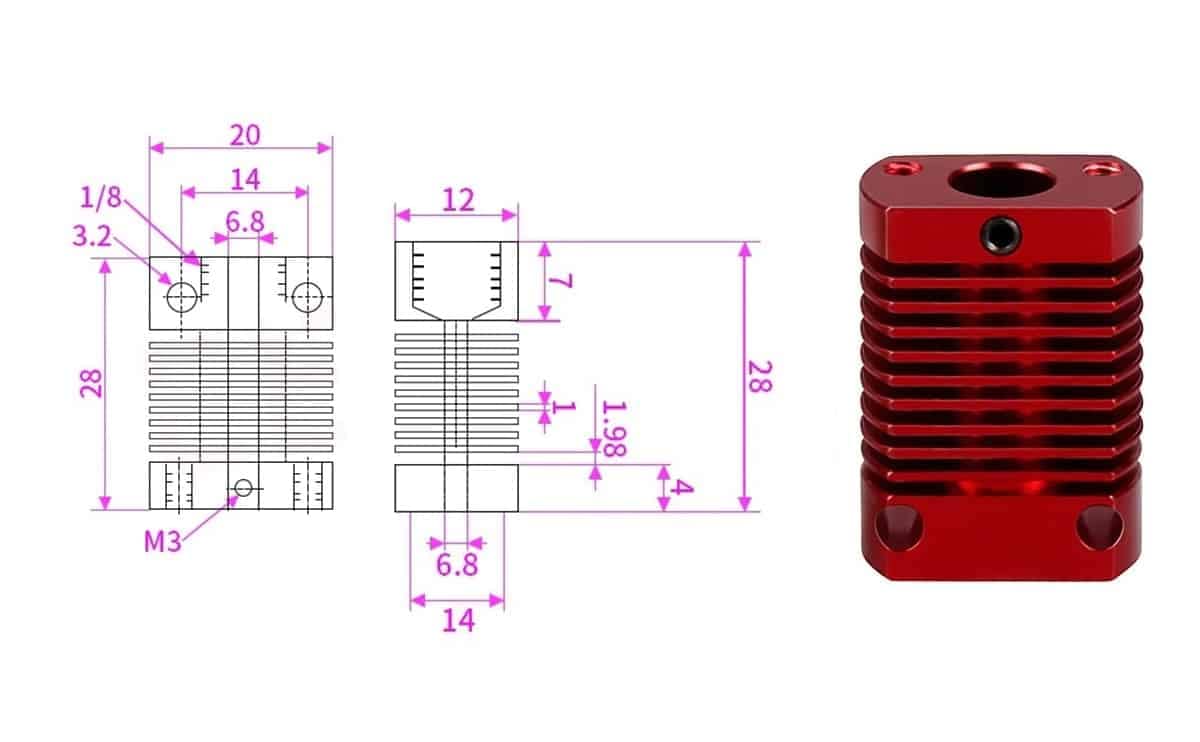

Specifications extruded heat sink:

- Material: Aluminum Alloy.

- Size: 28*20*12mm.

- Color: Red.

Package Includes:

- 1 x CR10 Heatsink.

| Weight | 20 g |

|---|

3 reviews for CR10 Heatsink Hotend Extruder Kit Heat Sink for CR10 CR10S 3D printer

Q & A

It will be on another side

Fits the stock Ender 5 Plus parts however, since the inside is also powder coated, the throat does not go all the way to the end and even for the 70-80 that it goes it, needs a lot of pressure.

To make it fit, I used by dremel and run a brass brush on the inside which removed the powder coating and then it was a smooth fit.

If its self-fabricated, then the coating ought not to be applied on the inside, alternatively it should be removed before selling because not everyone has the tools to do so.

Thanks for your feedback sir, We will solve this issue.